BE THE FIRST TO KNOW

Enter your email below to subscribe to the QLA newsletter to receive timely updates from your favorites products.

Unlike Balanced Pressure Systems, the pressurised loop system uses a known amount of sample.

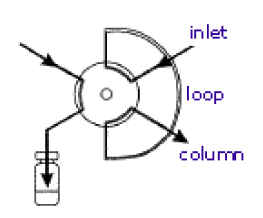

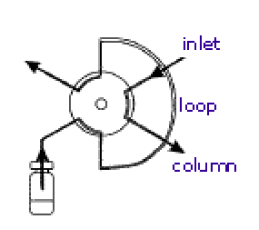

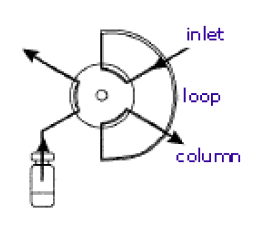

This technique typically uses a six-port valve, as shown in the figure below. It initially thermostats and pressurises the vial as in the previously described techniques (step 1). After pressurisation, the valve is turned and the loop is filled with the sample (step 2). Once the loop has been filled, the valve is turned again to redirect the gas flow and flush the sample into the transfer line leading to the analytical column.

|

|

|

| Step 1 Sample reaches equilibrium/pressurisation |

Step 2 Sample is extracted from headspace |

Step 3 Sample is injected |

This type of system allows high temperatures to be used but it also suffers from the same disadvantages as the balanced pressure system (i.e. sample carry over and the fact the injection port is always occupied).