BE THE FIRST TO KNOW

Enter your email below to subscribe to the QLA newsletter to receive timely updates from your favorites products.

|

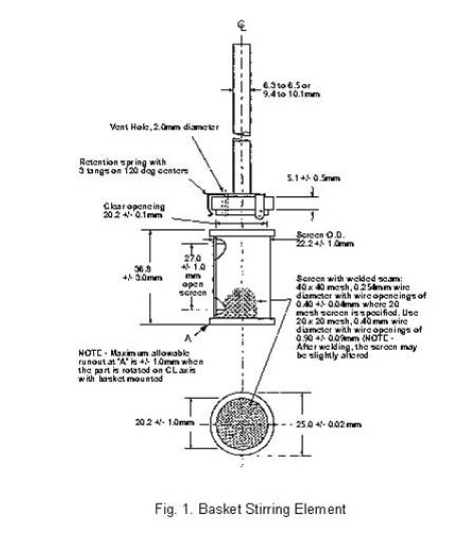

Adopted in 1970 the rotating basket method of dissolution testing was the first official method. The apparatus consists of a metallic drive shaft connected to the cylindrical basket. The basket is positioned inside a vessel made of glass or other inert, transparent material. The temperature of the media inside the vessel is kept constant by a water bath or heating jacket. The solution in the vessel is stirred smoothly by the rotating stirring element. The diagram (left) shows a simple graphic of the rotating basket set-up. This is very tightly specified however and the official drawing according to the USP is shown below. The drawing shows a basket manufactured from mesh, connected to a basket hub of with a vent hole by the use of clips. The Basket hub is connected to a rotating shaft. Every parameter of those individual parts is specified. The shafts and baskets must rotate freely and within specified limits, and importantly, they must be accurately centered in the vessel and be free from wobble. The validation of these parameters will be covered in a later chapter. The standard basket consists of a stainless steel 40 mesh construction, but there are many variations depending on the monograph and application. For example, suppository baskets are manufactured from PTFE with vertical slits to facilitate dissolution.

|

|

Mesh size refers to the number of openings per linear inch and the diameter of the wire used to create the mesh is specified. If the basket is reactive with the dosage form then it can be coated with PTFE or an inert substance such as gold or titanium. The diagram shows that the basket is connected to the rotating shaft by use of clips onto a basket hub. The basket hub also has a specific dimension and importantly, a small vent hole at the top to allow air to escape from the basket should it become trapped. It is important that this hole does not become clogged over time. Some baskets are supplied for use without clips, and use a push-on O-ring instead. While these are excellent for many applications, it is important to show that the results from this design are the same as the results obtained with clips - a process known as equivalence. It is by no means guaranteed that the results will be the same in every case. It is also important to note that different dissolution tester manufacturers will manufacture their baskets and hubs to slightly different specifications but all within the USP guidelines. Even though they look similar, baskets are not interchangeable between different tester manufacturers. Labhut tightly controls the manufacture of these items to ensure that they are compatible with the stated bath. There are a number of issues associated with baskets and the basket method which will be discussed next. |