BE THE FIRST TO KNOW

Enter your email below to subscribe to the QLA newsletter to receive timely updates from your favorites products.

Sampling can present the opportunity for a number of errors, especially for multiple point dissolution tests.

Placing sampling devices in the media can have an immediate effect on the hydrodynamics in the vessel, especially if they are large, such as a pipette for example.

The position where the sample taken is important and defined

The USP states:

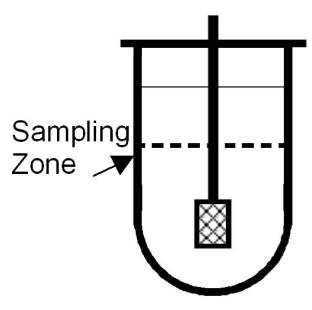

'Within the time interval specified, or at each of the times stated, withdraw a specimen from a zone midway between the surface of the Dissolution Medium and the top of the rotating basket or blade, not less than 1cm from the vessel wall'

The zone is clearly interpreted as a horizontal area in the vessel. 1cm away from the vessel wall to ensure that the media is free flowing.

Because the depth is defined as above, the actual position will be dependent on the total test volume. Thus for a 1000ml, 900ml or 500ml test, the sampling position will be different in each case and different cannulae may be necessary.

Differences in sampling position could potentially lead to errors with readings since the concentration cannot be assumed to be linear throughout the vessel. Techically there is also a small difference between the paddle and basket sampling positions as the top of the paddle sits a little lower than the top of the basket, although the difference is small.

There are a variety of sampling devices available, but as a rule, anything large, such as a pipette tip, should be avoided. The most common are sampling cannulae fitted with a filter on the end (see about dissolution filtration in an earlier page). Some manufacturers suggest the use of resident probes which stay in the vessel all the time. If this is to be successful then the diameter of the probe must be small enough not to affect the hydrodynamics in any way, and the use of filters inside the vessel must be avoided.

Where sampling is automated then the sampling cannulae are automatically lowered to the correct height and the samples taken using a pump. In the case of automation, correlation must be shown between the readings obtained automatically and manually.

If samples are taken manually then the correct depth must be reproducibly obtained by using a stopper on the cannula to prevent it moving through the vessel cover by different amounts each time. (see about Sample Introduction in an earlier page).

There are a variety of sampling cannulae available. The most common are manufactured using stainless steel or PEEK and range from 1/16" or 1/8" diameter. Resident cannulae must be a good deal smaller than that.

Samples should be taken at the allotted time within a 2% time window. For short dissolution tests, this can present a challenge and it may be necessary to start the test in each vessel at different times - a so called staggered start. With automated systems, samples from every vessel are taken at the same time.

The cannula should be lowered to the appropriate point and an aliquot of sample taken into a suitable syringe. (Glass or all-polypropylene are recommended. Plastic syringes with rubber tips should be avoided because of possible contamination from the rubber tip).

It is a good idea to take more sample than is needed for the test. A small amount of sample should be gently back-flushed back into the vessel to avoid turbulence but to wash off any particles from the filter surface.

Care should be taken with filtration and adsorption issues if appropriate (see previous page).