BE THE FIRST TO KNOW

Enter your email below to subscribe to the QLA newsletter to receive timely updates from your favorites products.

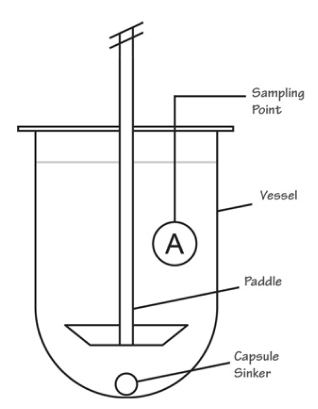

The Rotating Paddle, although Method 2, is actually the most widely used method in dissolution testing. Originally developed by Poole (1969) and was refined by scientists at the FDA for Drug Analysis in St Louis. The specifications for Apparatus 2 are identical with those for Apparatus 1 except that the paddle is substituted for the rotating basket.

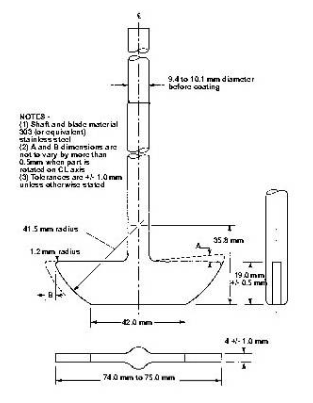

The dimensions of the paddle are closely controlled. Any variations can easily have a detrimental effect on reproducibility from vessel to vessel. For this reason, paddles should be treated as a precision piece of equipment, stored correctly, and inspected regularly for scratches, dents or other imperfections.

The dissolution test relies on uniform flow patterns and any imperfections can lead to turbulent flow. For that same reason, wobble and other deviations must be tightly controlled with specifications similar to the basket test.

|

SerialisationAs with the basket test, the paddles should be individually serialised, preferably with laser etching. If detachable paddles and baskets are used - spin on/spin off paddles, then serialisation should be on the shaft as well as the paddle section. |

|

Allowable VariationsPolyfluorocarbon CoatingPTFE or other suitable coatings are permitted by the USP, and have been widely used. The purpose of the coating is to reduce the interaction between steel and the dosage form. As steel quality improves, the need for coating reduces, but care should be exercised to use paddles of suitable steel quality. Polyfluorocarbon coating is a high temperature process and is difficult to gain a consistent thickness over the paddle. Poor coating and handling leads to flaking of the coating. This exposes the steel but can also disrupt the flow with the rough surface. Re-coating is an expensive option and easily avoided by storing the paddles in a suitable rack. Many users simply keep paddles and baskets in lab drawer - a sure recipe for a short life span. Another alternative is to use a paddle manufactured from solid PTFE or similar material. These paddles have the same dimensions as the steel paddles specified by the USP, but because they are solid, the coating cannot peel off. |