BE THE FIRST TO KNOW

Enter your email below to subscribe to the QLA newsletter to receive timely updates from your favorites products.

All of our columns are manufactured according to a strict ISO 9001:2000 protocol. There are four key Stages

Stage 1: Hydrothermal treatment Stage 2: Deactivation Stage 3: Wetting, bonding and crosslinking Stage 4: Quality control

Cronus GC columns use only the best possible fused silica tubing. The internal diameter of the tubing tightly controlled and the polyimide outer coating is capable of withstanding high temperatures without loss of flexibility or mechanical strength.

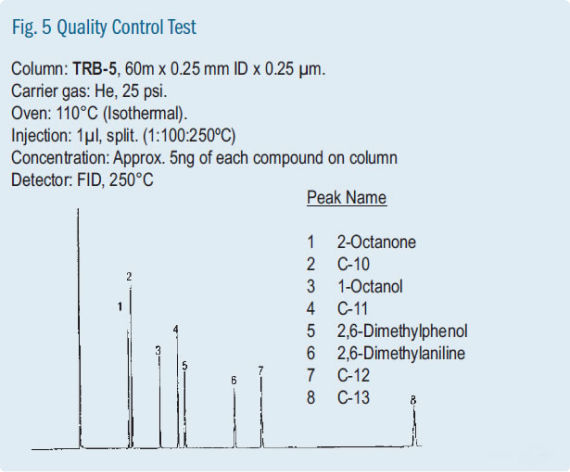

As silica tubing is made using very high temperatures there is often a large difference in the surface properties, particularly the amount and density of silanol sites. We initially treat the tubing to ensure that these are maximised and consistent throughout the length of the column as this is important for the coating process. (The silanols are later deactivated)

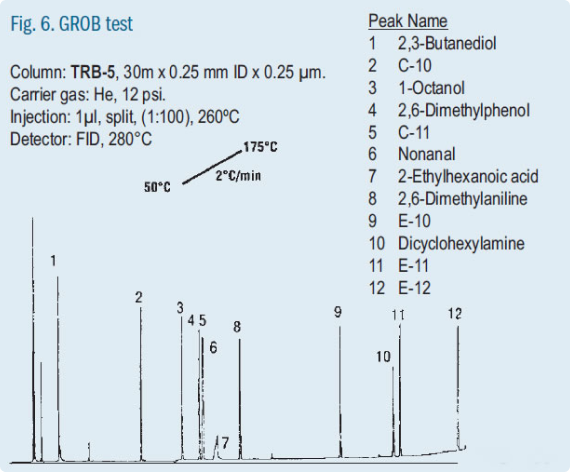

The deactivation process is carefully controlled (fig. 2), ensuring that the tubing surface has acquired the necessary chemical inertness and surface tension in before proceeding with stationary phase deposition. This step introduces specific functional groups on the tubing wall which are very useful for binding the stationary phase or to give the columns a given characteristic. The level of deactivation required is dependent on the final phase.

Cronus uses extremely pure polymers for its phases, in order to guarantee that our columns will meet your analytical requirements in terms of efficiency, reproducibility, stability and minimal bleeding.

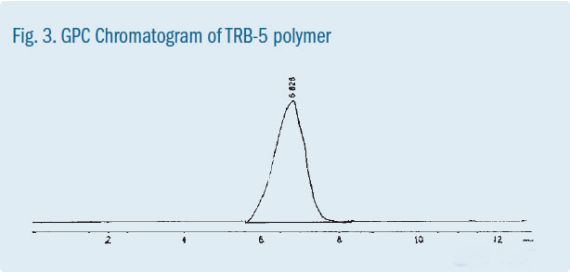

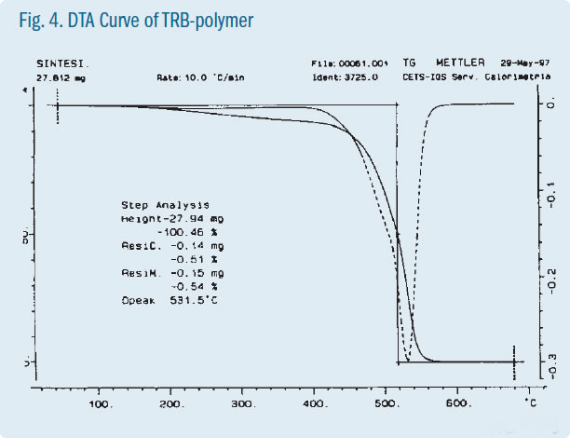

The polymers used are carefully fractionated to eliminate low molecular weight components and trace catalysts. This results in a higher thermal stability and lower bleeding. These polymers are tested by FTIR, UV, NMR, and other chromatographic (GPC) techniques and by differential thermal analysis.

Fig. 3 shows the molecular exclusion chromatography of the polymer TRB-5 with its corresponding thermogravimetric curve in Fig. 4.

The crosslinking and bonding of the stationary phase is achieved without the use of peroxides which are the cause of many of the problems found in other manufacturer’s columns. Peroxides are often the cause of phase degradation and thermal instability.

Crosslinked and/or chemically bonded stationary phase columns can often be regenerated by washing with solvents if it is accidentally contaminated.

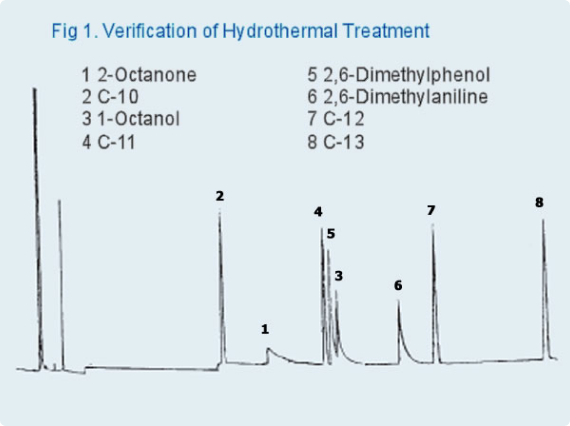

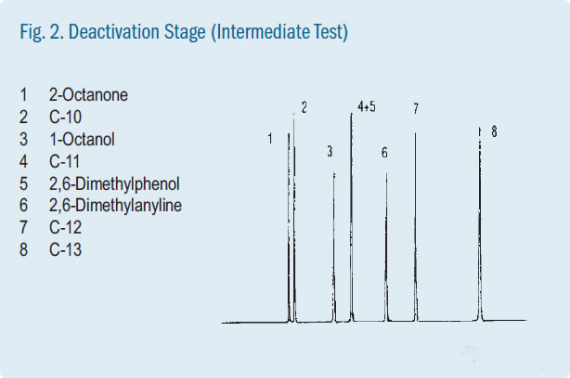

When you buy a Cronus capillary column you receive a product designed and manufactured to meet all of your quality criteria.

Each column is individually tested using a strict Quality Control Test (fig. 5 and 6), and the accompanying test data is provided as the proof that the column meets our quality specifications and your expectations.